Glossary

In this website, in documents and some communications via mail we usually adopt many technical terms because of they are a part of our business. In order to facilitate the communication we are used to employ abbreviations and acronyms which are international standard for PCB field; however, in order to be clearer for interested people, in this page there is a glossary with all technical terms and abbreviations employed with their meaning.

Example:

with the service FAST PCB the hole minimum size is greater than or equal to 0.35mm

The requiered minimum of annular ring is 0.20mm (pad size will be: 0.75mm=0.35+0.20+0.20mm)

Text such as company name, logo, or part number that is correct reading on the top copper layer will insure the layers are oriented correctly. This orientation text can be placed inside or outside of the board outline. Text placed outside of the board outline will be used for reference only and deleted prior to manufacture.

through our service Prod PCB it can be quoted up to 30-layers. If your board has a higher layer count, please complete our online Custom Quote personalized form.

This is an example of an Excellon drill file. It will have X & Y coordinates with tool sizes viewable in any text editor. This is the file that governs your finished hole sizes and locations.

A Sample Excellon File:

M48

;Layer_Color=9474304

;FILE_FORMAT=4:3

METRIC,LZ

;TYPE=PLATED

T01C0.300

T02C0.356

T04C0.635

T05C0.800

%

T01

X016685Y01045

X016765 Y000425

X004365 Y000425

X004285Y-03816

X0026Y02337

X016685 Y-03816

X016765 Y01045

T02

X00815Y000425

X02055Y01045

X0219Y001075

Flexible circuit boards are often used as connectors in various applications where flexibility, space savings, or production constraints make the use of rigid circuit boards impossible. In addition to cameras, a common application of flexible circuits is in computer keyboard manufacturing; most keyboards made today use flex circuits for the switch matrix. Flexible circuits are available through the Custom Quote Service.

In an effort to support the RoHS initiative, PCB Online offers several options that comply with the directive. All of the laminate material, soldermask material, and silkscreen material supplied are compatible for assembly at lead free solder temperatures and do not contain (above the upper limits) any of the restricted materials. There are several options for surface finishes for RoHS compliance: Immersion silver, ENIG (Full Feature only), OSP (Full Feature only), electrolytic gold (Full Feature only)

RoHS compliance applies only to the printed circuit board “as shipped” and PCB Online retains no responsibility for RoHS compliance of the printed circuit board after any subsequent processing or component placement by our customers or their assemblers.

With assembly technology SMD, copper layer is on the components layer, or on the top layer of the schede. In order to avoid that you project would be stopped, it needs to add a word text on copper layer (for example LS/LC or the code name of the PCB) to highlight it; this simple expedient will avoid the confusion about copper orientation allowing a correct drilling.

Multilayer PCB are composed of a number of copper layers between the outer layers. These copper layers are called inner layers. The sequence to build the inner layer is very important and it’s determinated by their denomination. Usually it’s just a numeration from n. 2 and so on.

Below an example of 6 layers PCB denomination:

Strato •Top

INTERNO 2

INTERNO 3

INTERNO 4

INTERNO 5

Strato •Bottom

It’s important that the denomination and the exstension of file’s names which contain layout data are clear and complete for every PCB software and his engineers.

an electronic device so built will be called Surface Mount Device (SMD). In the electronic field it has almost substitute the assembly with through-hole technology (THT).

Both kind of technology can be useful for the same PCB if it needs to assemble components not suitable to surface mount such as big transformers and semiconductor of power.

A SMT component is usually smaller than the opposite part with through-hole, it could have small plug or different kind of cables, flat contacts, ball grill array (BGA), or terminations on the component.

It needs to follow some rules to obtain a correct result with this special material:

– Minimum carbon gap is 0.400mm (16mil)

– Minimum carbon line width is 0.300mm (12mil)

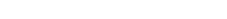

Last years, also thanks to components such as BGA (Ball Grid Array), FBGA (Fine BGA), UFBGA (Ultra Fine BGA) a new technology for printed circuits develop the so called blind holes and buried holes:

A blind hole is a standard vias hole PTH, but it links just a single outer layer with one or more inner layers, not passing completely through the PCB thickness, applied with a controlled depth on Z axis of the board. This procedure allows to obtain high density of connections for every surface unity and it becomes almost inevitable when the disigner needs to add on pcb components very innovative in small places. Blind holes with small size are made with laser of precision.

A buried hole is a PTH hole which links one or more inner layers, not connecting with outer layers, in this way the hole is completely buried in the PCB and invisible from the outside.

In order to realize blind holes and/or buried holes for your design it’s necessary to use the Custom Quote Service in which you can add file with specifications’ data about holes, specifying this special building procedure in Note (being a particular manufacturing, we have to judge the file in order to confirm the design feasibility and give you a custom quotation).

We recommend testing all surface mount boards and multilayer orders.

PCB Online, in order to guarantee the best reliability towards its customers, apply the 100% electrical test on every printed circuit board manifactured without additional cost.